Such an investment would be a boost to the UK’s cardboard recycling sector. Current mills operate largely at capacity, with the UK a major exporter of paper for recycling (waste paper). In 2020, 3.84 million tonnes was exported, with the UK mills having used 3 million tonnes of waste paper.

Cyclelink UK, which is part of Cyclelink International, the global sourcing arm of China paper giant Shanying International, has started plans to source material for the plant and secure licensing approvals for its operation.

It is expected that the plant would produce a form of dry pulp largely made from used cardboard from supermarkets and other retailers, as well as cuttings from box making plants. The thick sheet of secondary pulp could then be exported to China for use in papermaking.

China currently bans the import of waste paper, and increasingly mills within China are using more internal secondary material or virgin pulp or businesses are importing finished product from mills in south east Asia.

The size of the plant has not been disclosed but it is expected to be in the range of 150,000-250,000 tonnes.

Details

Gary Waters, managing director of Cyclelink UK and director for logistics at Cyclelink International, told letsrecycle.com that while the company could not comment on the plans at this time, “details would be available in the coming months”.

On its website, Cyclelink notes that “due to China’s rapidly depleting forest resources, wood pulp is becoming increasingly scarce and regenerated fibre has become the main raw material for the paper industry”.

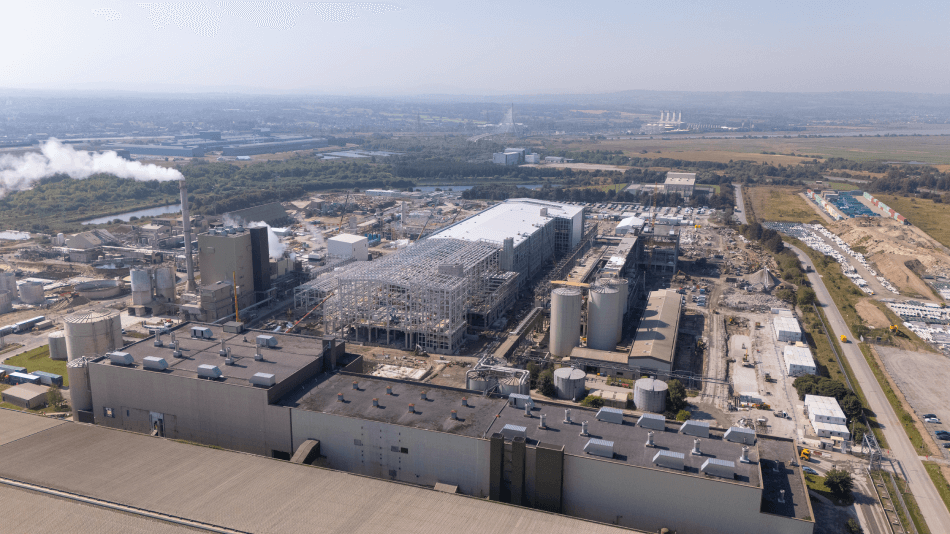

- Development of the dry pulp plant comes as the UK is also set to see the conversion of the UPM Shotton newsprint mill by new owner Eren Paper, a Turkish carboard and corrugated packaging business.

Subscribe for free