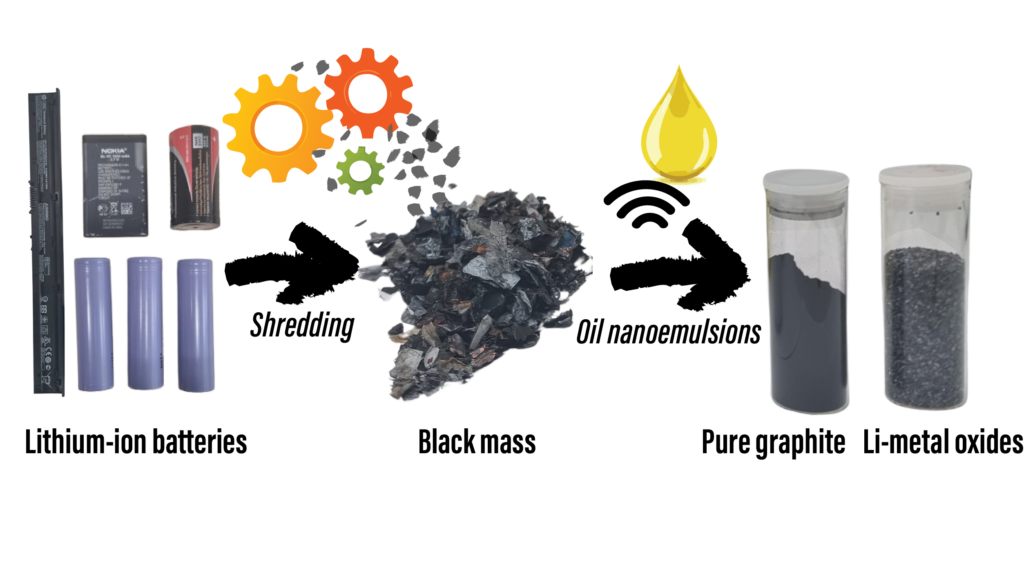

With the method thought to be a cheaper and better solution to making the switch to greener technologies, the technology, patent-pending, is said to allow lithium-ion battery black mass, a low value mixture of anode and cathode and other materials.

Working under the Faraday Institution’s ReLiB project, Professor Andy Abbott and Dr Jake Yang found the way of the recovering valuable battery-grade metal oxides from crushed batteries by using nanoemulsions created from a trace of cooking oil in water.

Although oil and water do not mix unless soap is added, research has shown that using ultrasound can create nano-droplets of oil that are stable for weeks. Oil nano-droplets are found to purify battery waste commonly known as ‘black mass’ as it contains a mixture of carbon (graphite), lithium, nickel and cobalt metal oxides (NMC).

The oil nano-droplets stick to the surface of the carbon, acting as a ‘glue’ to bind hydrophobic graphite particles together to form large oil-graphite conglomerates which float on water, leaving the valuable and hydrophilic lithium metal oxides untouched. The oil-graphite conglomerate can be skimmed off leaving pure metal oxides.

Short-loop

Current recycling techniques use a combination of furnace heat treatment to burn off the undesired graphite, as well as concentrated corrosive acids. The Leicester-developed emulsion technique is designed to allow short-loop recycling of lithium-ion batteries. The battery-grade crystalline structure of the recovered material is not destroyed in this process and allows the remanufacturing of the recovered material directly back into new battery cells.

Yang said: “This quick, simple and inexpensive method could revolutionise how batteries are recycled at scale. We now hope to work with a variety of stakeholders to scale up this technology and create a circular economy for lithium-ion batteries.”

Subscribe for free