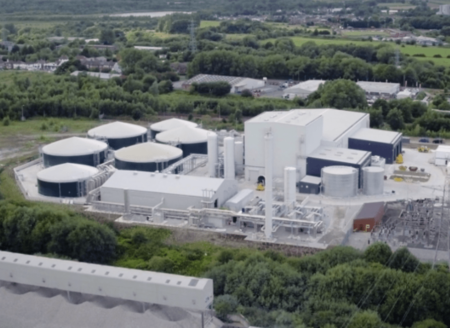

Danish-owned company Dong Energy (now Ørsted) announced plans for the Cheshire facility in 2015, claiming the plant was a “first of its kind” facility to treat unsorted residual waste using enzymes to create a ‘bioliquid’ and solid recovered fuel.

This would, the company claims, separate recyclable material from residual waste using a patented technology

However Ørsted’s 2017 annual report, which was released earlier this year, stated that the self-funded plant was not operational as planned in 2017 and now expects to be ready for commissioning by June.

The plant is currently, “in the process of ramping up to full capacity”, Orsted told letsrecycle.com. The plant is operating on municipal solid waste supplied by FCC Environment and the site has been producing clean electricity since December 2016, the company added. Orsted said the facility will be fully operational later this year.

Delays

The plant was initially scheduled to be fully operational in April 2017, which was then pushed back to July 2017 before it was later set for “early 2018”.

According to the 2017 annual report, the company “had been working to test and optimize the mechanical parts of the plant, which has taken longer than previously assumed”.

Speaking to letsrecycle.com a company spokesperson said that despite the setbacks, things are now working as planned and confidence remains high. They said: “As we are utilising a first-of-its-kind technology we have experienced some challenges along the way, however we remain confident about the plant’s ability to prove the significant potential of the REnescience technology.”

The spokesperson added: “The core enzymatic process is working as expected and output in the form of bioliquid and recyclables are also up to expectations. We are now finalising the optimisation of the plant’s mechanical operation, which has taken longer than expected.”

In February 2018, Cobalt Energy announced that it had completed construction at the REnescience site, with process commissioning now under way.

Orsted expects the plant to process 120,000 tonnes of unsorted household waste annually, which corresponds to the waste from approximately 110,000 British households.

REnescience Technology

According to Orsted, the facility will work by mixing together warm water and the waste inside a sealed vessel, alongside enzymes which will break down all organic matter. Once organic matter has been extracted recyclable materials can be recovered alongside a solid recovered fuel fraction. Inert materials, such as sand, gravel and glass, are also recovered for reuse as aggregates.

The separated organic material is recovered as a thin bioliquid, which is digested by bacteria within a sealed anaerobic digestion vessel to produce biogas. A digestate product will also be produced from the AD phase of the process.

REnescience Northwich received planning consent from Cheshire West and Chester council in February 2016.

Subscribe for free