And, waste management company Viridor has applied to accept mixed municipal waste at its Runcorn EfW plant, which is also in Cheshire and is the largest such facility in the UK.

Covanta is developing theProtos facility in partnership with Biffa. Private equity firm Macquarie’s Green Investment Group (GIG) was also previously involved.

The waste management companies reached financial close on the facility, which is located near Ellesmere Port and is expected to be operational in 2024, in December 2020 (see letsrecycle.com story).

In documents published with Covanta’s application, the company says it was “not clear” whether the facility would be of a single stream design or a two-stream design at the time of the last permit variation, in January 2019.

Covanta signed a joint engineering, procurement and construction contract with Greek industrial conglomerate Mytilineos and German construction company Standardkessel Baumgarte for the design, build and construction of the facility in December 2020.

The facility will now be two-stream, the documents say. As such, Covanta is applying to the Environment Agency to make “a number of changes”, including upping the plant’s capacity, “to align with the final designs for the facility.”

The Agency has launched a consultation on the proposals which runs until 20 July.

A spokesperson for Covanta told letsrecycle.com the facility already had planning permission to process up to 600,000 tonnes per annum, so this would not need changing.

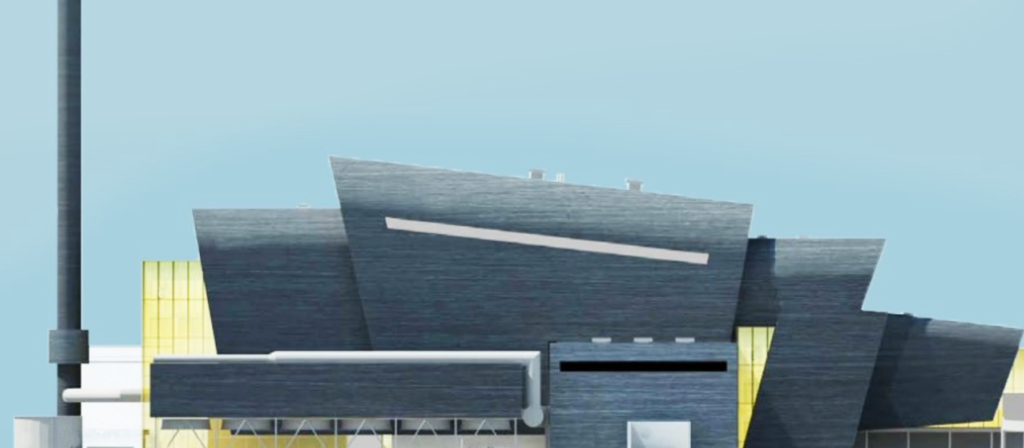

Protos

Once the Protos plant is up and running, it will treat non-recyclable household and commercial and industrial waste. It will be capable of generating 49.9 MWe of electricity, using a steam turbine from energy recovered from flue gases.

Covanta will supply the plant with operations and maintenance services, while Biffa will provide fuel. More than 60% of the feedstock to be sourced from the waste management company’s own operations.

The other changes proposed in Covanta’s application include revising the installation’s boundary, altering the location of the stack and updating the number of emergency diesel generators, among other things.

Owned by global investment business EQT Infrastructure, Covanta is involved in four EfW projects in the UK. These include the Protos plant, Rookery South in Bedfordshire, Newhurst in Leicestershire and the Earls Gate Energy Centre in Grangemouth, Scotland. Only Rookery South is operational.

Covanta increased its share in the four plants in March, buying out GIG (see letsrecycle.com story).

Mixed municipal waste

Meanwhile, the Environment Agency is also consulting on Viridor’s application to vary the permit for its 1.1 million tonnes per year capacity Runcorn EfW plant.

According to documents submitted with Viridor’s application, the proposed new waste type is considered “highly similar in nature and composition” to several waste codes already accepted at the site.

These include the non-composted fraction of municipal, animal and vegetable waste, off-specification compost and digestate from the anaerobic treatment of municipal, animal and vegetable waste.

Accepting mixed municipal waste will not cause “any greater environmental risk” nor require any operational changes to the site, the documents say.

“Viridor is cognisant that there is significant demand for the processing of both recyclable and non-recyclable waste as part of a responsible waste management solution for the UK,” the documents read.

“This permit variation being sought in respect of Runcorn ERF will allow more non-recyclable waste to be diverted from landfill and instead be used to generate low carbon heat and power, contributing to both resource and energy efficiency.”

Viridor’s application also includes the removal of the direct discharge of digestate to the feed hopper and updates to reflect that air pollution control residues (APCR) are now sent off-site for recovery.

The Agency’s consultation on the proposals runs until 4 August.

Letsrecycle.com contacted Viridor for comment.

Runcorn

The Runcorn EfW plant treats a range of non-hazardous waste types, most of which is refuse derived fuel (RDF), but also some (C&I) wastes and source-segregated packaging.

Waste material arrives either by rail or road and is weighed before proceeding into the tipping hall. There, it is tipped into an RDF bunker of sufficient capacity to hold several days’ worth of waste.

The facility has a total capacity of approximately 360 megawatts (MW) of thermal input and generates approximately 74MW of electrical power and 53 MW of steam per hour.

Subscribe for free