The company, which also has a site in Wellingborough, near Northampton, handles around 50,000 tonnes of waste pallets and wood each year. As well as providing woodchip for the panelboard manufacturing industry, the company recycles wood into animal bedding.

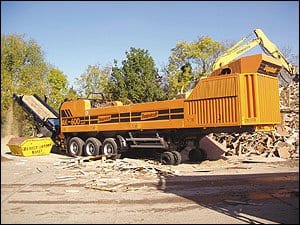

The new shredder, the company's fifth purchased from Doppstadt in the last three years, will initially increase capacity by 700 tonnes of waste wood a week. But the new 571hp machine will eventually see Larner Recycling processing a total of 1,400 tonnes a week, over 72,000 tonnes a year.

Larner Recycling's new Doppstadt hammermill shredder will increase production by 700 tonnes a week |

Commenting on the new machine, Larner Recycling's managing director David McEwan said: “We anticipate that there will be at least a steady increase in wood recycling over the next four to five years, and the AK 600 will give us the extra capacity we need to expand accordingly.”

Mr McEwan said the company's other Doppstadt machines have delivered “the efficiency and reliability we require”, while ease of operation and maintenance contributed to Larner Recycling's purchasing decision.

With a list price of 225,000, the AK 600 has a drive engine separate from the shredding unit, which allows for easy access during servicing and improved safety through the minimisation of dust build-ups in the engine. The machine also uses a load-sensing device to automatically reverse the feed roller when the amount of material being fed to the hammermill is too great.

Potential damage from contaminated wood is kept to a minimum by a hydraulic sensor that activates an accumulator system to remove contaminated material.

Doppstadt sales director George Kehoe explained: “Our aim is to provide equipment which helps our customers to maximise throughput and bottom line competitiveness, while producing material which meets the market requirements.”

Subscribe for free