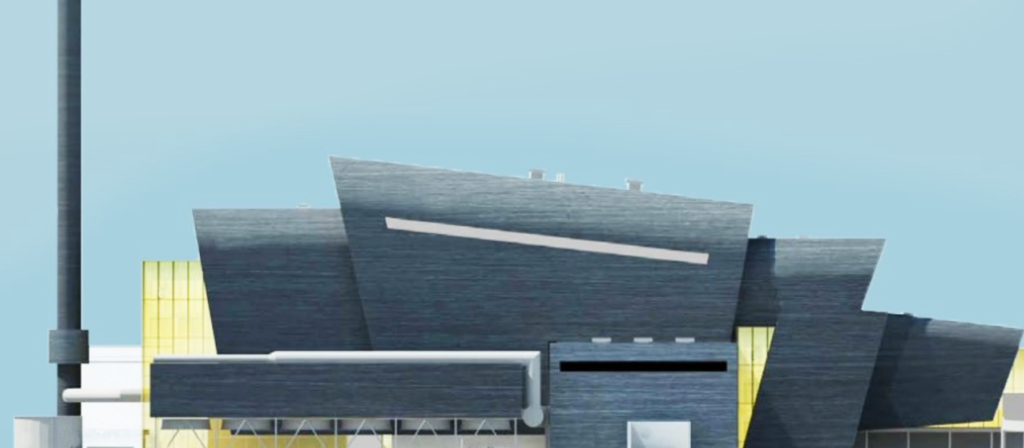

The technology will be applied at both the Newhurst and Protos plants Covanta is building in partnership with Biffa.

The long-term agreement will see O.C.O take “significant tonnage” of air pollution control residue (APCr) per year from the two facilities.

APCr is typically a mixture of ash, carbon, and lime and is left over after combustion gases are treated.

O.C.O will use its “pioneering accelerated carbonation technology” to turn the waste into an aggregate known as manufactured limestone.

O.C.O said the process enables the permanent capture of CO2 and ensures the plants can meet their zero waste to landfill goals.

Covanta has recognised the huge potential our technology offers

- Lizzie Bayley, O.C.O’s legal and commercial manager

Potential

Lizzie Bayley, O.C.O’s legal and commercial manager who led negotiations, said: “We are delighted that the partnership with Covanta has recognised the huge potential our technology offers for both APCr recycling and safe and sustainable carbon capture.

“It demonstrates the faith that the waste sector has in O.C.O’s abilities to make a tangible difference to the way APCr is managed and enables us to invest further in expanding our network of facilities.”

Treatment

An estimated 14,000 tonnes of APCr will come out of the Newhurst site and a further 17,000 tonnes from Protos, O.C.O said, with treatment taking place at its existing operational facilities, including its plant in Leeds, as well as a new facility to be constructed in Norfolk.

The process treats APCr with carbon dioxide gas to “enable the permanent capture of significant amounts of CO2, turning it into the world’s first carbon negative artificial aggregate for use within the construction and civil engineering sectors”.

Andrew Howie, commercial director at Covanta Europe, said: “We are delighted to be working with O.C.O, their world leading technology provides a sustainable and carbon neutral solution to help us recycle the APCr residues.

“O.C.O’s process creates a carbon negative product for aggregate supply that supports Covanta’s active engagement in the circular economy.”

Subscribe for free