At the same time, the company disclosed that it will be also be investing £7 million in a plant to process 20,000 tonnes per annum of pots, tubs and trays (which are usually made from polypropylene (PP) and PET.

The company is already a major recycler and supplier of HDPE material from used milk bottles from its plant in Redcar.

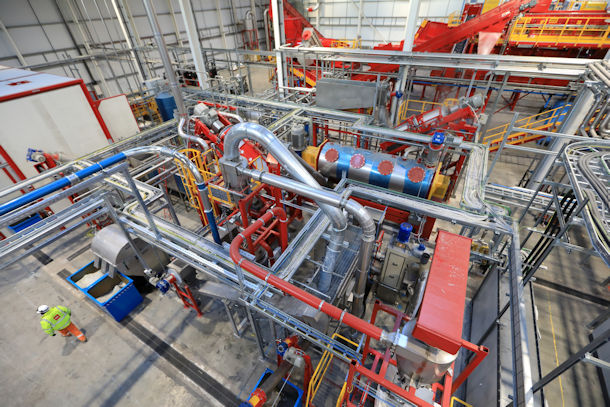

The new Seaham plant is capable, said Biffa, of processing 1.3 billion plastic bottles a year describing it as a“state-of-the-art recycling facility” which ranks “among the most modern and technically advanced in the world”.

Opportunity

Biffa says that it sees plastic recycling as a “significant investment opportunity” partly because of a potential UK ban on the export of plastics for recycling and restrictions in South East Asia as well as UK plans for a plastic tax and for a deposit return scheme.

Alongside these developments, the company expects changes to extended producer responsibility as likely to boost demand for recycled plastic material for use by blowmoulders and brands. Biffa has also highlighted that increasing capture rates are expected in order for future Plastic Pact and government targets to be met.

Northern Powerhouse

Henri Murison, director of the Northern Powerhouse Partnership, is officially opening the plant and he said: “Biffa’s decision to invest in this new, state-of-the-art facility in Seaham will be yet another step in our ambition for the North to close the productivity gap and work towards an extra 850,000 jobs by 2050 by transforming our economy for the better.

“Not only will it help to reduce our overall plastic consumption as a society, it puts the Northern Powerhouse at the heart of the latest recycling capability and is another important step towards a more environmentally sustainable future that the North is uniquely well placed to lead the country and globally.”

“This facility will help the UK address two of its most pressing issues – plastic waste and the climate emergency.”

Climate emergency

Commenting on today’s opening, Biffa chief executive Michael Topham said: “This facility will help the UK address two of its most pressing issues – plastic waste and the climate emergency. Whilst we must work towards reducing overall plastic consumption as a society, the fact remains that plastic has a vital role as a lightweight, durable, low energy-intensity material, that if recycled properly can have a sustainable role in modern life. Facilities like ours at Seaham will help ensure that we can recycle our own plastic waste here in the UK, creating jobs in the green economy and stimulating the development of more sustainable packaging.”

High-purity

Giving more details about the Seaham project, Biffa said it will “convert PET back into high-purity plastic pellets to be sold on to drinks makers and other manufacturers to be used for a range of applications, from food and beverage packaging, to clothing. Biffa believes the plant will play an important role in reducing plastic pollution in the UK by improving the country’s ability to recycle through sustainable closed loop systems.”

The plant, said the company, will provide 100 full time jobs in the region, building on Biffa’s established presence in the North where it already employs around 1,600 people.

Revenues

The new facility is expected to generate £40m in revenues per year and is said by Biffa to be “of strategic significance as the Group continues to expand its nationwide recycling capabilities. The plant will capitalise on the access to plastic waste that Biffa has through its collections and sorting activities, including the 4.1m tonnes of waste and recycling the Group collects from UK households and businesses every year.”

The Seaham facility also builds on Biffa’s existing capabilities in plastics recycling, including its plant in Redcar, North Yorkshire, where it recycles HDPE plastic milk bottles back into food grade recycled HDPE – 85% of milk bottles sold in the UK are now said to contain Biffa recycled plastics.

MRFs

To facilitate the growth of its plastics recycling work Biffa been upgrading its network of MRFs (materials recycling facilities) to expand sorting capacity. Future plans for its plastics recycling work include further expansion of its HDPE capacity of about 14,000 tonnes.

Subscribe for free